Published on Dec. 22, 2025

Achieve outstanding wean-to-finish results in your herd

The wean-to-finish phase is where careful management turns healthy piglets into market-ready animals. Performance depends on two essentials. First, maintain consistently high health status so pigs can express their full genetic potential. Second, manage the post‑weaning transition with care, especially the first seven days. This early period drives feed intake patterns, resilience and overall growth curve for the entire batch.

The first seven days after weaning

The first week frames success for the cycle. Focus on stability, access, and observation.

Day 0 to 2

Ensure pigs find feed and water quickly. Keep feeder pans lightly covered to stimulate exploration. Verify every pen has enough functional nipples and correct water flow. Introduce supplemental feeding in trays if intake is hesitant.

Day 3 to 5

Fine‑tune feeder settings as group behavior stabilizes. Check water again and remove any blockages. Confirm temperature, humidity, and ventilation settings track the environment curve for nursery pigs.

Day 6 to 7

Consolidate routines. Gradually increase feed presentation if refusals are low. Record pen‑level notes on consumption, behavior and any unevenness so adjustments can be made before growth differences widen.

Proper feeder settings & water settings, supplemental feeding and proper ventilation setup are a reliable checklist for this period. Consistent daily routines lower stress and keep intake regular.

Feeder management and diet strategy

Feeder setup influences feed conversion ratio and average daily gain.

- Keep pan coverage moderate to encourage activity without waste.

- Adjust gates so feed flows without bridging. Observe pigs at peak activity to decide if more or less presentation is needed.

- Use phased diets that match gut maturity. Typical progression is pre‑starter, starter, grower and finisher.

- Choose feed form and particle size for the target age. Pelleted or crumbled starter diets often improve early intake and FCR.

- Review nutrient density, enzymes and functional fiber for gut health (adapt to regional regulations on medications and additives).

Consistent feed management, coupled with timely adjustments, reduces variation between pens and improves overall batch uniformity.

Water management and hydration

Pigs that do not drink will not eat, which directly impacts performance. Verify three things in every room and pen. Access, flow, and quality.

- Access: Provide enough nipples or bowls so pigs can drink without conflict.

- Flow: Nursery pigs need adequate flow to drink quickly without fatigue. As pigs grow, reassess flow and pressure.

- Quality: Check for off‑flavors, sediment or microbiological issues. Calibrate medicators and clean lines on a routine schedule.

Daily checks prevent hidden hydration issues that erode intake and growth.

| Nursery | Grower-finisher | |

|---|---|---|

| Pigs/water source | 10 | 10 to 12 |

| Flow rate |

0,5-1,0 L/min (0,13-0,26 gal/min) |

1,0 - 1,5 L/min (0,26-0,40 gal/min) |

| Water pressure |

<1,4 bar (<20 PSI) |

1.0-2,8 bar (15-40 PSI) |

| Parameter | Normal |

|---|---|

| Nitrate dissolved, mg/L | <45 |

| Sulfate dissolved, mg/L | <250 |

| Chloride dissolved, mg/L | <250 |

| Iron, ml/L | <0,2 |

| Total hardness, mg/L CaCO3 | <800 |

| Total dissolved solids, mg/L | <1500 |

| Manganese, mg/L | <0,05 |

| Sodium, mg/L | <200 |

| pH | 6,5-9 |

| Bacteria, coliforms /100mL | 0 |

Creating the right environment for success

Temperature, humidity, ventilation, and gases

Comfort drives appetite. Match room conditions to pig age and weight. You need to keep thermal comfort stable during the first week to avoid drafts and sudden temperature drops. Regarding the ventilation set-up, balanced fresh air with heat retention maintains air quality without chilling pigs. Make sure to provide consistent lighting so pigs move, eat, and drink confidently. Finally, control ammonia, carbon dioxide, and hydrogen sulfide, because poor air quality reduces feed intake and increases stress. Proper ventilation and clean air reduce respiratory burden and support uniform growth.

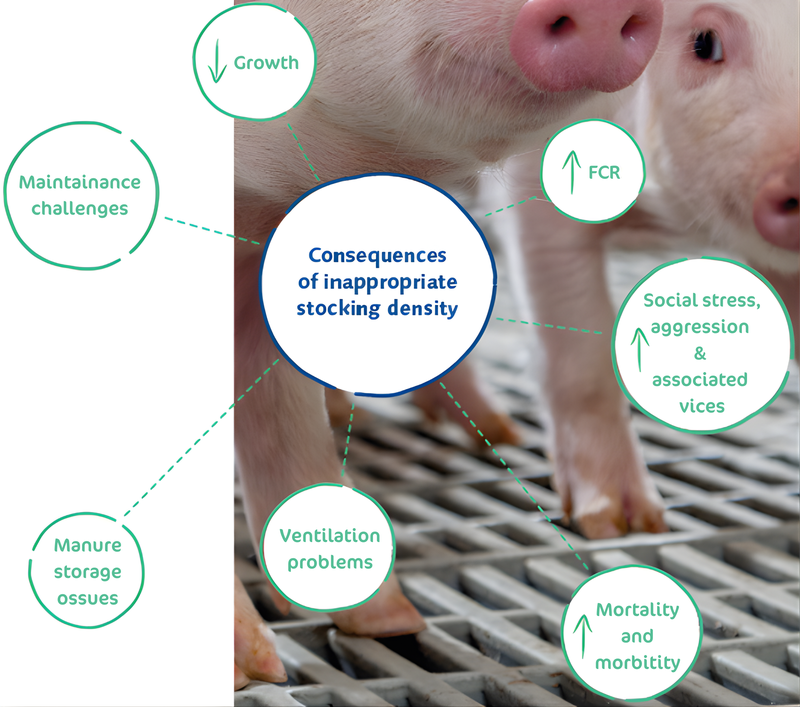

Space allowance and pen design

Adequate floor space is essential for optimal growth and behavior. When stocking density is too high, timid pigs fall behind and variation increases. Use pen designs that minimize dead corners, improve feeder and drinker access and allow farmers to enter and observe pigs easily.

Health status and biosecurity

A high health status is the foundation of good wean to finish results. Keep traffic flow simple, respect clean and dirty lines and maintain routine sanitation. Align vaccination and parasite control with local veterinary guidance. Stable health reduces performance dips and medication use.

Everything is about observation and routine

Successful barns run on consistent routines. Here are a few more tips we can give you to ensure the best wean to finish set-up for your farm.

- Visit pens at the same times

- Watch how pigs approach feeders and drinkers

- Note groups that are less active, noisier, or uneven

Small interventions early prevent bigger problems later. For further insights and visual guidance, explore our Wean to Finish Vlog.